coatible

researches for a plastic-free future through:

Recycling

Migration protection

Recycling

Our packaging solutions for the food industry are made of cardboard and can be fed directly into the waste paper cycle as a mono-material.

Migration protection

Thanks to bio-based coatings, food is completely protected from the migration of unwanted substances that are harmful to health.

Plastic prevention

The plastic inner bags in food packaging can be eliminated with our solutions. The layers used are applied directly to the packaging board and are completely bio-based, natural and compostable.

Mission

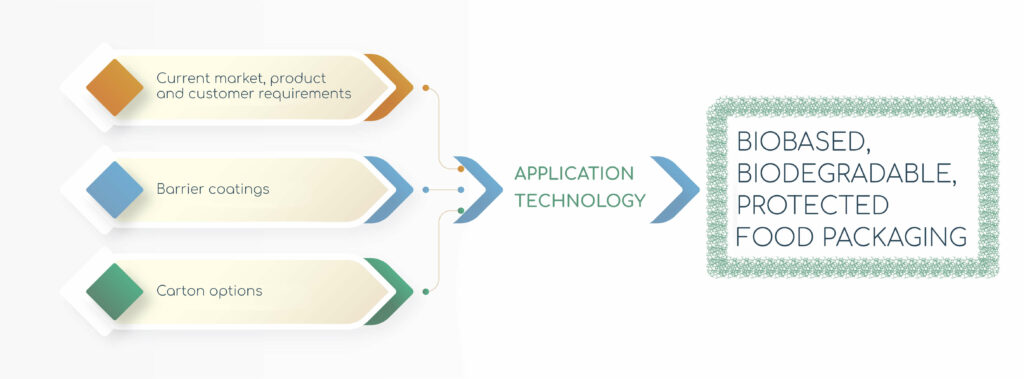

coatible develops bio-based and biodegradable barriers and a compatible application process. And this individually for each application.

Vision

The use of coatable barriers eliminates the need for plastic films as additional inner packaging for food products.

Even without plastic wrapping, food in coatible packaging will be protected from the migration of undesirable substances. coatible packaging meets the requirements of “food safety” for direct contact with food. The plastic films around frozen pizzas alone represent 3000 tonnes of PE film in Germany.

Targets & Technologies

18 months

Research & Planning

1.5 years

Preparation

Start was in April 2022 – by the end of 2023 coatible will have developed market-ready products!

The developed barriers allow the use of recycled GD2 cardboard. Due to the biodegradability of the barrier, the packaging product made of GD2 cardboard remains fully recyclable.

coatible is oriented towards specific market requirements and moderates important stakeholders of relevant value creation processes towards clear goals